The choice of submersible led lights material is crucial because the lamps that are immersed in water for a long time. Stainless steel under water lights generally have 3 type: 304, 316 and 316L , but they differ in corrosion resistance, strength and service life. let's see how to distinguish whether the volt underwater lights you bought is made of 304 or 316/316L stainless steel.

(1) Check the volt underwater lights identification and certificates

Formal underwater led lights manufacturers will mark material information on underwater low voltage lights products, such as "316 stainless steel" or "316L stainless steel". Some specific underwater led lights products may also come with material test reports or quality certification certificates as an important basis for judging the material.

(2) 12 volt underwater led lights magnetic test

304, 316 and 316L stainless steel are all austenitic structures, usually non-magnetic or weakly magnetic. You can use a magnet to perform a simple magnetic test on the lamp to determine whether it is made of stainless steel.

(3) lumitec underwater lights difference in chemical composition

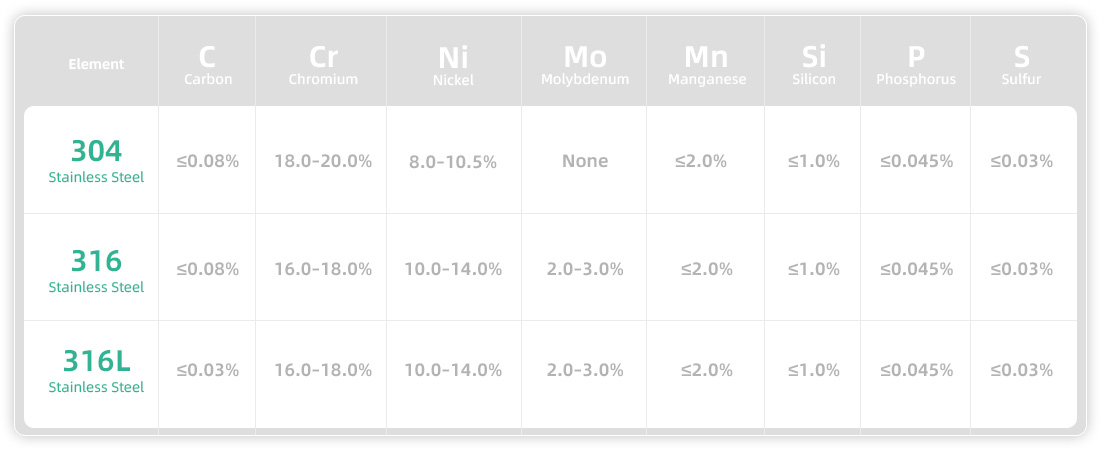

304 stainless steel corresponding the elements:0Cr18Ni9,316 is 0Cr17Ni12Mo2.

In the other hand,304 stainless steel nickel content is 9% and 316/316L is 12%.

what’s the most important,316/316L stainless with the Molybdenum element which make the corrosion resistance is further enhanced.

304(NI) content: 9%,316/316L(NI) content:12%

304(Mo)content:0%,316/316L(Mo) content:2-3% ! (Better corrosion resistance!)

(4) Corrosion resistance test

The deep glow 12v underwater lights you buy can be tested for simple corrosion resistance. You can use a bucket of salt water, put all the underwater pool lights into the bucket of salt water, and observe whether there will be corrosion after a period of time. 316 and 316L stainless steel show stronger corrosion resistance in chlorine-containing environments, while 304 stainless steel may show slight signs of corrosion.

(5) Price comparison

Different materials of waterproof underwater lights will result in different prices. 316 and 316L stainless steels are more corrosion-resistant due to the addition of molybdenum, and their cost is usually higher than 304 stainless steel.

Shenzhen Heguang Lighting Co., Ltd. has nearly 20 years of experience in the research and development and production of low voltage underwater pond lights. If you have any other questions about the material or purchase of underwater led lamps, please feel free to contact us:

Email: info@hgled.net

Tel: +86-13652388582

Good corrosion resistance 316L underwater lamps LED you can clink the link :

Post time: Mar-21-2025