Heguang lighting applied structure waterproof technology in swimming pool lighting area since 2012.The structure waterproof is achieved by pressing the silicone rubber ring of the lamp cup, cover and pressing ring by tightening the screws.

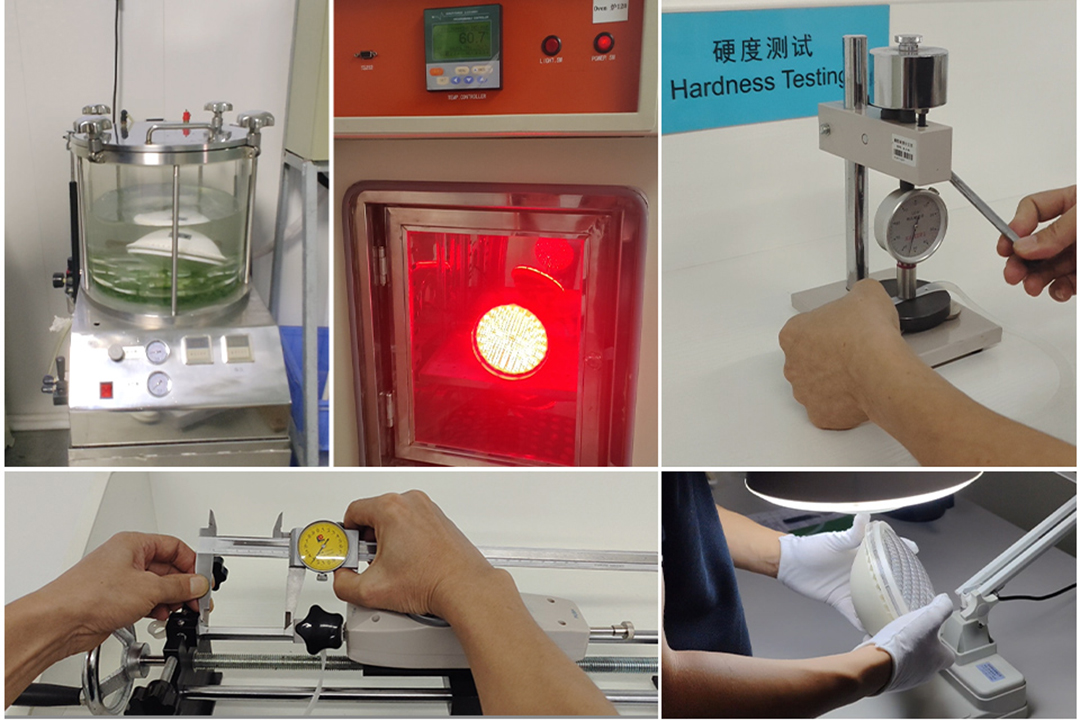

Material is very important parts to the structure waterproof technology,we do many test for the material and we list some of the test :

1. Chemical reaction test on 316 stainless steel screws :

Method :Drop M2 chemical analysis liquid on the surface of stainless steel screws,power on for 5 seconds to observe whether red color appears and will not fade in a short time.

Performance: the molybdenum content is not less than1.8%,the material is 316 stainless steel .

2. Silicone ring High and low temperature test :

Method : 60 minutes 100℃ and -40℃ high and low temperature test,then doing the tensile strength, tensile rebound and hardness tests

Performance : the hardness should be 55±5, degree A. tensile force is at least 1.5N per mm² and will not break after one minute.The tensile rebound test requires stretching the length of the silicone ring by one time. After 24 hours, the error of silicone ring length is within 3% .

3. An-ti UV test :

Method : Put the transparent PC cover at 60℃,8 hours respectively testing under the 340nm and 390nm to 400nm wave length,cyclic aging for at least 96 hours.

Performance :lamp surface no discoloration, yellowing, cracking, deformation, light transmittance is not less than ninety percent of original after Anti UV testing.

4. Lamps high and low temperature Aging Test

Method : 65℃ and -40℃ cyclic impact testing for 10000 times, then 96 hours continuously lighting testing.

Performance : lamp surface is intact,no discoloration,no deformation or melting.the lumen and CCT value are not less than ninety five percent than original,no bad phenomenon such as unable to start of the power supply,the lamp fail to light up or flicker.

5. Waterproof test (include salt water)

Method : Soak the lamp in disinfectant water and salt water respectively, turn it on for 8 hours, and turn it off for 16 hours for continuous testing for more than 6 months.

Performance :There is no rust spots, corrosion or cracks on lamp surface. There should be no water mist or water drops in the lamp and the lumen and CCT value are not less than 95% than original.

6. High-pressure waterproof test

Method :120 seconds, 40 meters of water depth high-pressure waterproof test

Performance :There should be no water mist or water drops in the lamp.

After all the above tests, the lamp is disassembled to ensure that the deformation of each part is less than 3%, and the resilience of the silicone ring is more than 98%.

All the products need to take 100% ten meters water depth pressure test before shipment. Heguang products now already hot selling in European market for more than 10 years, and the reject rate is controlled within 0.3%.

With the professional experience of underwater pool lights production,Heguang lighting surely can be your reliable supplier !

Post time: Jan-04-2023